1. Engineer should scrape the bottom and wall and stir A-part and B-part separately in their own barrels thoroughtly, the stiring time should not less than 60s.

2. Mix equal weight or volume of A-part and B-part together in one container, and stir the mixed glue thoroughtly until the color become even gray, the blending time should not less than 60s

3. Then let the glue stand for some time to allow the bubbles to escape naturally. If possible, the mixed compound can be vacuum degassed by applying a vacuum of 10-20 mmHg for 5 minutes or until no bubbles emerge.

4. Finally, pour the glue into the product to be potted within the specified working time and let the potted products in room temperature for curing. Complete curing needs 8 to 24 hours. The curing process accelerates in higher summer temperatures and slows down in lower winter temperatures. The curing time decreases as the temperature increases (refer to the table below for details):

|

Temperature

|

Cure time

|

|

70°C

|

40 min

|

|

100°C

|

25 min

|

1. Since there is a slight difference in viscosity between parts A and B, if using machinery for potting, the pressure on part B may need to be slightly adjusted.

2. his product may not cure or may only partially cure when in contact with certain substances. These include compounds containing sulfur, phosphorus, or nitrogen such as polysulfone, polythioether, polyurethane, substances containing amides or amines, materials containing elements like tin, arsenic, antimony, selenium, tellurium, some unsaturated hydrocarbons, and plasticizers. It is advised that operators who smoke should wash their hands with soap before handling this product, as smoking can leave sulfur residues on the hands.

3. During use, the product's viscosity may fluctuate slightly, but this will not affect its performance.

PAKCOOL® TPC-200 Two-part High-Transparency Encapsulant for Fiber Lasers

|

|

|

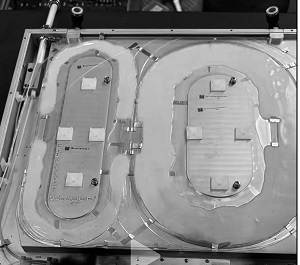

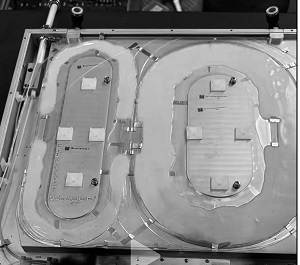

PAKCOOL® TPC-200 is a two-part transparent potting material which cures at room temperature or heating can accelerate the curing. TPC-200 has lower viscosity and can fill in the tiny gaps among fibers and heatsink. After curing, TPC-200 exhibits excellent optical transparency, high and low temperatures resistance and electrical insulation. The cured material has low hardness and exerts low stress to components or fibers due to temperature variations during operation, very suitable for encapsulating and fixing fibers on the water-cooling plate.

TPC-200 is non-hydrophilic and moisture-proof, which can effectively reduce the impact of humidity on fibers and extend fibers’ lifespan

|

|

PAKCOOL® Two-part Thermally Conductive Encapsulant TPC-213-UR for Heat Dissipation and Moisture Protection in Fiber Laser Systems

|

|

|

Chooyu's PAKCOOL® TPC-213-UR/TPC-219-UR are specially designed two-part potting material with thermal conductivity of 1.3W/m▪K/1.9w/m*K, both parts are white color. TPC-213-UR/TPC-219-UR cures at room temperature and heating can accelerate the curing. Upon curing, a gel-like thermally conductive elastomer is formed with minimal stress to electronic components or fibers, very suitable for encapsulating and fixing fibers on the water-cooling plate and promoting the heat dissipation from fiber to the cooling plate. TPC-213-UR/TPC-219-UR are non-hydrophilic and moisture-proof, which can effectively reduce the impact of humidity on fibers and extend fibers’ lifespan.

|

|

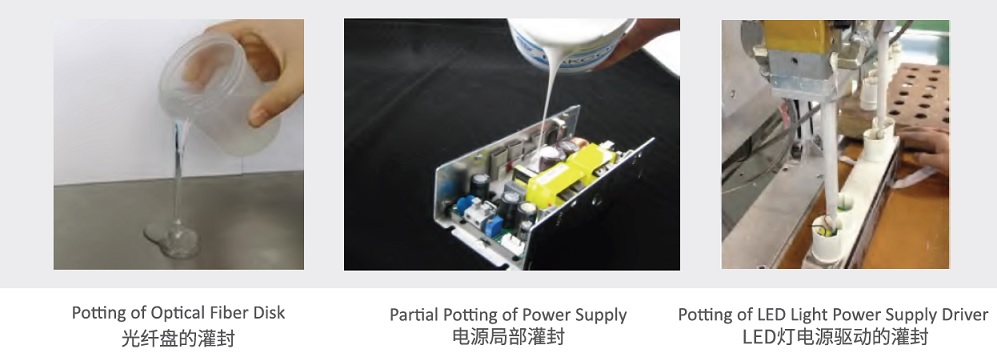

Typical Applications of PAKCOOL® Thermally Conductive Encapsulant

返回列表

返回列表