PAKCOOL® One-part Moisture-cure Thermally Conductive RTV Silicone Adhesive Specification

|

Product Name

|

Color

|

Thermal conductivity(W/m·K)

|

Viscosity(cP)

|

Tack free time(min)

|

Density(g/cm³)

|

Hardness

(Shore A)

|

Shear strength(MPa)

|

File

|

|

TC-100-MR

|

Black

|

-

|

paste

|

5

|

1.34±0.10

|

39

|

2.4

|

TC-100-MR

|

|

TC-100

|

white

|

0.75

|

non-flowable, paste

|

3

|

1.59±0.10

|

56

|

1.8

|

TC-100

|

|

TC-110

|

white

|

1.3

|

non-flowable, paste

|

5

|

2.28±0.10

|

76

|

2.6

|

TC-110

|

|

TC-115

|

white

|

1.5

|

non-leveling

|

4

|

2.60±0.10

|

76

|

2.2

|

TC-115

|

|

TC-120

|

white

|

2.0

|

non-leveling

|

4

|

2.81±0.15

|

81

|

2.7

|

TC-120

|

|

TC-125

|

white

|

2.5

|

non-leveling

|

5

|

2.96±0.15

|

82

|

3.0

|

TC-125

|

|

TC-130

|

white

|

3.0

|

non-flowable, paste

|

2

|

2.96±0.15

|

83

|

1.9

|

TC-130

|

|

TC-135

|

white

|

3.5

|

non-flowable, paste

|

2

|

3.13±0.15

|

89

|

1.8

|

TC-135

|

|

TC-140

|

white

|

4.2

|

non-flowable, paste

|

3

|

3.17±0.15

|

90

|

2.2

|

TC-140

|

PAKCOOL® One-part Heat-cure Thermally Conductive Adhesive Specification

|

Product Name

|

Thermal conductivity(W/m·K)

|

Viscosity(cP)

|

Density(g/cm³)

|

Cure time(min)

|

Hardness

(Shore A)

|

Shear strength(MPa)

|

File

|

|

TC-9100

|

-

|

440,000

|

1.60±0.20

|

10@150℃

|

55±15

|

2.3

|

TC-9100

|

|

TC-9110

|

1.0

|

80,000

|

2.50±0.20

|

10@150°C

|

80

|

5.3

|

TC-9110

|

|

TC-9115

|

1.5

|

110,000±50,000

|

2.60±0.10

|

60@150°C

|

72.5±12.5

|

2.6

|

TC-9115

|

|

TC-9118-H

|

2.0

|

70,000

|

3.00±0.20

|

10@150°C

|

94

|

6.1

|

TC-9118-H

|

|

TC-9120

|

1.8

|

750,000±200,000

|

2.70±0.15

|

30@150°C

|

70±10

|

1.1

|

TC-9120

|

|

TC-9130

|

3.0

|

80,000

|

3.25±0.20

|

5@150°C

|

93

|

4.5

|

TC-9130

|

|

TC-9140

|

4.0

|

120,000

|

3.10±0.20

|

10@150℃

|

94

|

5.5

|

TC-9140

|

Packaging Specifications for PAKCOOL® One-part Moisture-cure Thermally Conductive RTV Silicone Adhesive

|

PAKCOOL®TC-1xx series One-part Moisture-cure Thermally Conductive RTV Silicone Adhesive is offered in various packaging options: 330mL cartridge packaging or customizable according to customer requirements.

|

Operating Guide for PAKCOOL® One-part Moisture-cure Thermally Conductive RTV Silicone Adhesive

1. Surface Cleaning:

Clean the surface of the object where the adhesive will be applied, removing any oil, dirt, or impurities.

2. Application of Adhesive:

Cut a small opening at the tip of the adhesive cartridge, insert it into a caulking gun, and apply the adhesive to the cleaned surface.

3. Curing:

After applying the adhesive, quickly join the bonding surfaces together and expose the assembled parts to air. The curing time depends on environmental humidity/temperature and the depth of the adhesive layer. It is recommended that the adhesive depth does not exceed 5mm. The surface will dry and fully cure in approximately 7 days.

-

1. Ventilation: It is recommended to use the product in well-ventilated areas to minimize odors.

-

2. Usage: Try to use the entire contents after opening. If not used up in one go, remove any cured part before subsequent use.

-

3. Safety Information: Please refer to the product's Material Safety Data Sheet (MSDS) for safety details.

Packaging Specifications for PAKCOOL® One-part Heat Cure Thermally Conductive Adhesive

|

PAKCOOL®TG-91xx series One-part Heat Cure Thermally Conductive Adhesive is offered in various packaging options: 30mL and 55mL dispensing syringes, 330mL cartridge packaging, or customizable according to customer requirements.

|

Operating Guide for PAKCOOL® One-part Heat Cure Thermally Conductive Adhesive

1. Preparation and Storage:

This 1-part heat-curing product should be stored in horizontal at <0°C immediately upon receipt. Before use, the product should be left at room temperature (about 25°C) for at least 2 hours to warm up. Once warmed, the product can be installed in a dispensing machine for normal use. The warmed up product is suggested to be used up within 3 days at around 25°C, not exceeding 5 days.

2. Application Method and Process: :

When dispensing, keep air pressure or piston pressure ≤0.6 MPa and control the amount of adhesive dispensed onto the heating (or cooling) surface by setting the dispensing pressure and time parameters.

This product series is suitable for reflow soldering processes, achieving optimal curing and bonding at about 150°C for 10 minutes. After reflow soldering, baking at 150°C for some time can enhance the bonding. Some products may require curing at 150°C for 30 minutes. The curing time extends at lower curing temperatures and the curing temperature is recommended not below 100°C, with a minimum curing time of 2 hours.

3. Unused Product:

Unused cartridge products are recommended to remove them from the dispensing machine and tighten the outlet cap for storage. For cartridge not used within 2 days, store in a freezer . Product should be used promptly after warming.

-

1.

Immediate Storage: Upon receipt, the product should be stored in a freezer immediately. Before use, allow the product to warm to operating temperature.

-

2. Viscosity and Storage: The viscosity of the product will increase over time during storage. Store at low temperatures and use as quickly as possible to avoid operational difficulties due to changes in viscosity.

-

3. Compatibility: This product may not cure or may only partially cure when in contact with certain substances. These substances include compounds containing sulfur, phosphorus, or nitrogen such as polysulfone, polythioether, polyurethane, materials containing amides or amines, and substances with tin, arsenic, antimony, selenium, tellurium, some unsaturated hydrocarbons, and plasticizers.

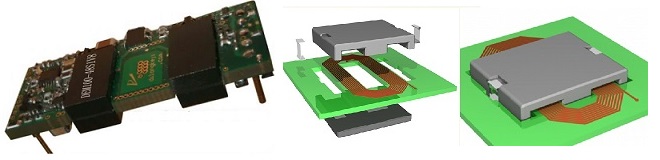

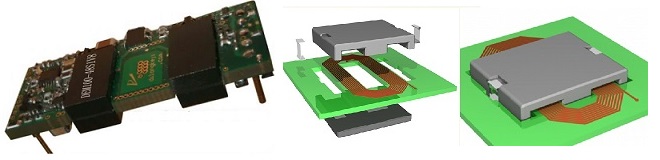

Use PAKCOOL® TC-9110/9120/9140 in Planer Transformer and Ultra Thin Power Modules

|

Chooyu's PAKCOOL® TC-9100 series production are high-performance One-part Heat Cure Thermally Conductive Adhesive with thermal conductivity from 1.0 W/m·K to 4.0W/m*K (ASTM D5470). TC-9100 series products have good adhesion to various materials such as copper, aluminum, stainless steel, and PCBs. Curing without the release of by-products, it can be used in large areas, deep areas, and completely enclosed situations. The TC-9100 series products can be used for bonding magnetic cores and PCBs in planar transformers, as well as for bonding magnetic cores and PCBs in high-power ultra thin power modules. After heated in 150°C for 10 minutes, TC-9140 can have hardness of 90 (ShoreA) and adhesive strength up to 5MPa.

|

|

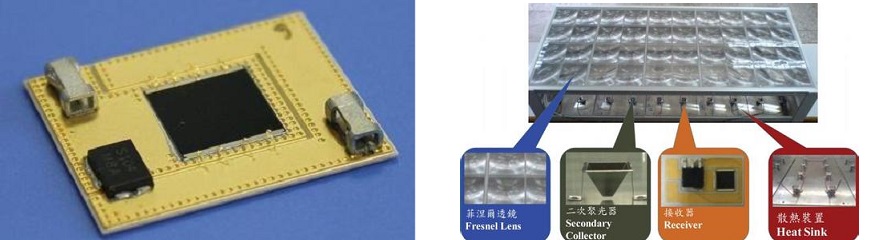

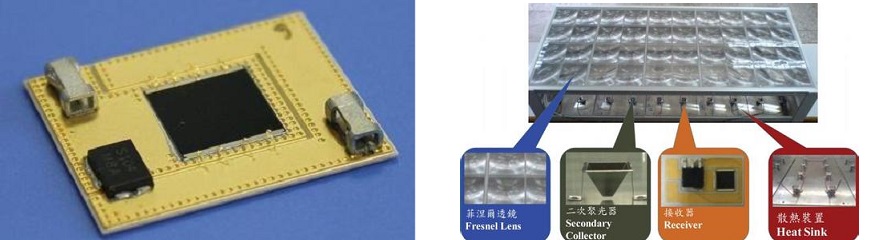

Application of PAKCOOL® TC-9110 on Concentrated Photovoltaic Power Modules

|

Chooyu's PAKCOOL® TC-9110 is a high-performance One-part Heat Cure Thermally Conductive Adhesive with a thermal conductivity of 1.0 W/m·K (ASTM D5470). Once fully cured, the adhesive strength exceeds 3 MPa, requiring heating to cure. This product is designed for stability and can operate long-term within a temperature range of -50°C to 200°C, maintaining consistent adhesive and thermal properties. It is ideal for use in High Concentration Photovoltaic (HCPV) cell modules, applicable either under the photovoltaic conversion module or directly on the backplate to bond the module to the back. Curing occurs within about 10 minutes at 150°C. Thanks to its excellent thermal conductivity, TC-9110 can transfer heat generated by sunlight exposure from the bottom of the module to the backplate, where it is dissipated into the air or removed by a cooling system attached to the backplate. The TC-9100 series products from Chooyu offer thermal conductivity ranging from 1.0 W/m·K to 4 W/m·K. Samples are available upon request for trial purposes.

|

根据客户需求,提供专业定制化服务。

返回列表

返回列表